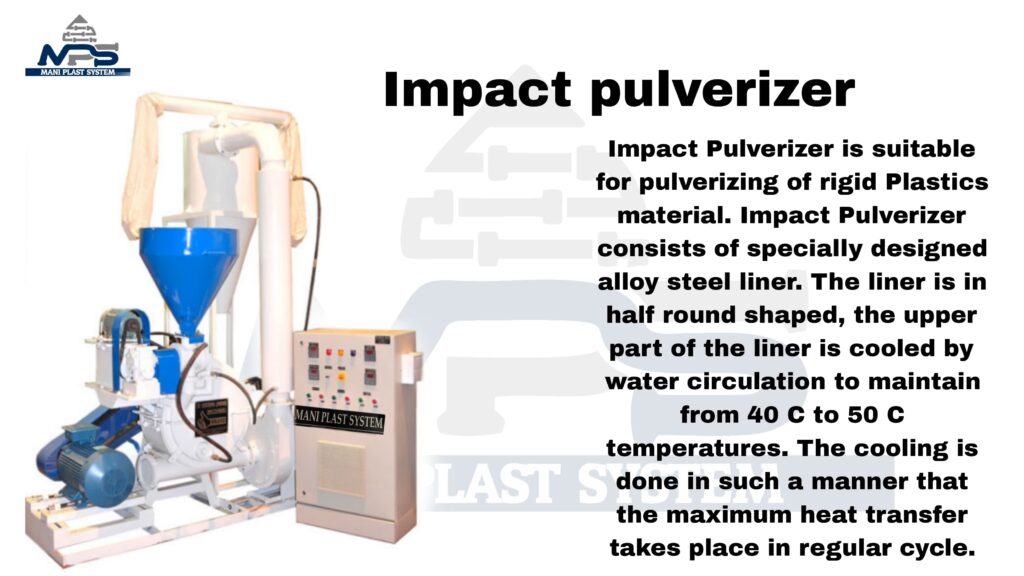

Impact Pulverizer

PVC Pulverizer: An Introduction

- A PVC pulverizer is a specialized machine designed to grind and pulverize polyvinyl chloride (PVC) plastic into fine particles or powder. This process is crucial for recycling and reprocessing PVC waste, as well as for preparing PVC materials for various industrial applications.

Key Features and Components:

- Grinding Mechanism: Typically employs high-speed rotating blades or hammers to shear and crush the PVC material.

- Cooling System: Essential to prevent overheating of the PVC, which can release harmful fumes. Cooling systems often involve water or air circulation.

- Sieving System: Separates the ground PVC into different particle sizes based on the desired application.

- Dust Collection System: Minimizes dust emissions and maintains a clean working environment.

Applications of PVC Pulverizers:

- Recycling: Reprocessing PVC waste from various sources, such as bottles, pipes, and packaging.

- Compounding: Preparing PVC powder for use in the production of new plastic products.

- Chemical Industry: Producing PVC powder for use in chemical processes.

Benefits of Using PVC Pulverizers:

- Efficient Recycling: Converts waste PVC into valuable raw materials.

- Reduced Environmental Impact: Minimizes landfill waste and conserves natural resources.

- Cost-Effective: Provides a cost-effective solution for processing PVC materials.

- Versatility: Can handle a wide range of PVC materials and particle sizes.

- By effectively pulverizing PVC, these machines play a vital role in promoting sustainable practices and reducing the environmental impact of plastic waste.

The following are the special feature of the machine.

HAMMER

- Sixteen hammers are fitted with rotary block one end is fixed with bolts and the other ends of the hammer are “V” shape teeth rack. These hammers rotate in clockwise direction with a certain space to the liner. Hammers are balanced to avoid vibration and gives smooth service.

COOLING JACKET

- Five water cooling jackets are provided to keep the entire body cool to maintain temperature.

BEARING HOUSING

- This is fabricated with MS body fitted with water jacket and good quality high speed bearing for longer and troubles free service.

FRAME

- Frame is fully reinforced to absorb any types of vibration during operation.

CONTROL PANEL

- Equipped with starter voltmeter, ampere meter, rotary switch and phase indicating lamps.

DOSING DEVICE

- Dosing Device for automatic feeding fitted with AC motor with variable drive to enhance smooth/uniform feeding.

CYCLONE

- Cyclone with water and air cooled conveyor pipe to keep Pulverized material cooled down for storage/recycle and to enhance production capacity.

IMPORTANT: It is observed that mixing of pulverized material by 10-15% with fresh PVC compound in Twin Screw extruder the production capacity is increased by 2% to 5% and get better gelatinous rate, which improves all properties of PVC pipe e.g. Impact Strength, Reversion, Short Term, Long Term test etc.Please Note: for betterment above specifications can be changed without prior notice.