Plastic Scrap Grinder: The Ultimate Solution for Recycling Efficiency

In today’s environmentally conscious world, managing plastic waste effectively has become a priority for industries and individuals alike. Plastic recycling is no longer just a sustainability initiative but a vital aspect of industrial operations. Among the tools that play a pivotal role in this process, the Plastic Scrap Grinder stands out as an indispensable machine, transforming plastic waste into reusable material with efficiency and precision.

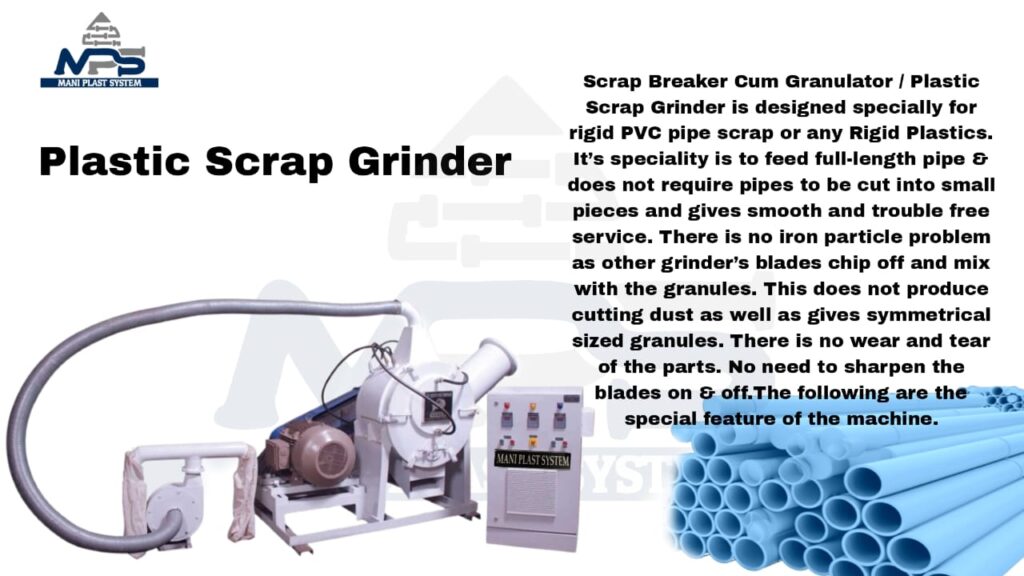

What is a Plastic Scrap Grinder?

A Plastic Scrap Grinder is a specialized machine designed to grind plastic waste into small, manageable pieces. These granules can then be reused in manufacturing processes, contributing to a circular economy and reducing the demand for virgin raw materials.

Typically used in industries like plastic manufacturing, recycling plants, and packaging, these grinders are the backbone of efficient recycling operations. Their ability to process various types of plastics, from thin films to rigid materials, makes them versatile and invaluable.

Features of Mani Plast System’s Plastic Scrap Grinder

Mani Plast System’s Plastic Scrap Grinders are engineered to deliver exceptional performance, durability, and ease of operation. Here are some of their standout features:

- High Grinding Capacity: Designed to handle large volumes of plastic waste, ensuring seamless recycling operations.

- Energy Efficiency: Built with low power consumption in mind, reducing operational costs while maintaining high productivity.

- Durable Blades: Equipped with robust and sharp blades that ensure consistent performance and long service life.

- Customizable Design: Available in various sizes and configurations to cater to the specific needs of different industries.

- Low Maintenance: User-friendly design with minimal maintenance requirements, ensuring uninterrupted operations.

How Does It Work?

The working mechanism of a Plastic Scrap Grinder is both simple and efficient. Here’s a step-by-step overview:

- Loading: Plastic waste is loaded into the machine through a hopper.

- Grinding: High-speed rotating blades grind the waste into fine granules.

- Output: The processed plastic is collected and ready for further recycling or reuse in production processes.

This streamlined operation not only saves time but also enhances productivity by delivering consistent results.

Benefits of Using a Plastic Scrap Grinder

Investing in a high-quality Plastic Scrap Grinder offers numerous advantages:

- Environmental Sustainability: By converting plastic waste into reusable material, these grinders play a crucial role in reducing environmental pollution.

- Cost Savings: Recycling reduces the need for raw materials, lowering production costs significantly.

- Improved Efficiency: High-speed grinding ensures faster processing times, enabling industries to manage waste more effectively.

- Versatility: Capable of processing various types of plastics, from polyethylene to polypropylene.

- Space Optimization: Reducing bulky plastic waste into compact granules saves storage space.

Industries That Benefit from Plastic Scrap Grinders

Plastic Scrap Grinders cater to a wide range of industries, including:

- Plastic Manufacturing: To recycle production scraps and reduce waste.

- Recycling Plants: Essential for converting post-consumer plastic into reusable granules.

- Packaging Industry: For managing leftover materials and scraps.

- Automotive Sector: To recycle plastic parts and minimize waste.

Why Choose Mani Plast System’s Plastic Scrap Grinder?

Mani Plast System is a trusted name in the industrial machinery sector, known for its commitment to quality and innovation. Here’s why their Plastic Scrap Grinder is the preferred choice:

- Proven Reliability: Backed by years of experience and a track record of satisfied customers.

- Superior Quality: Built with high-grade materials to ensure durability and performance.

- Tailored Solutions: Customizable options to meet the unique requirements of various industries.

- Exceptional Support: Comprehensive after-sales service to keep operations running smoothly.

Customer Success Story

One of Mani Plast System’s clients, a leading recycling plant, shared how their Plastic Scrap Grinder transformed their operations. With the machine’s high-speed performance and minimal downtime, the plant achieved a 30% increase in recycling efficiency, saving both time and resources. Such success stories underscore the value and impact of investing in quality equipment.

The Plastic Scrap Grinder is more than just a machine; it is a solution that drives sustainability and efficiency. By investing in a high-quality grinder from Mani Plast System, industries can not only reduce waste but also contribute to a greener future.

Ready to revolutionize your recycling process? Explore Mani Plast System’s Plastic Scrap Grinder today and take the first step toward sustainable industrial operations. Visit maniplastsystem.com for more information or contact their team for a personalized consultation.